科技工作者之家

科技工作者之家APP是专注科技人才,知识分享与人才交流的服务平台。

科技工作者之家 2018-09-03

《复合材料学报》优先在线发表论文。

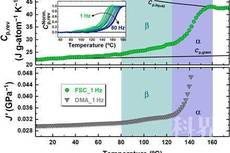

摘 要:通过分析固化度对环氧树脂体系的自由度和结合能的影响,对GIM(group interaction modelling)方法进行了拓展,研究了树脂材料性能随固化度的变化规律。以EPON862/DETDA体系为例,对拓展GIM方法进行了验证。研究结果表明,拓展GIM方法不仅可以准确预测完全交联EPON862/DETDA的材料性能,而且能预测非完全固化体系的玻璃化转变温度、体积收缩率、热膨胀系数及弹性模量随固化度的变化规律,以上结果均与实验和分子动力学模拟结果吻合较好。此拓展GIM方法可与固化反应动力学联合,为模拟环氧树脂在固化反应过程中产生的残余应力和变形提供准确的材料性能输入参数。

关键词:GIM方法;环氧树脂;材料性能;固化度

Abstract: An extended GIM (group interaction modelling) method was developed by considering the influence of conversion on the cohesive energy and the degrees of freedom of epoxy resin system, which can predict the relation between conversion and material properties of epoxy resin. The epoxy resin composed of epoxy EPON862 and curing agent DETDA was used as an example for validation of the extended GIM method. It is found that the extended GIM method not only accurately predicts the material properties of fully cured EPON862/DETDA system, including glass transition temperature, volume shrinkage, coefficient of thermal expansion and elastic modulus, but also well captures the trend of these material properties changing with the conversion throughout curing process. And good agreement is found by comparing predicted results with that obtained from the molecular dynamics (MD) simulation and experiments. As combined with curing kinetics, this extended GIM method is capable of providing accurate material properties as the input parameters for modelling the shrinkage strain and residual stress throughout the curing process of epoxy resin.

Keywords: Group interaction modelling; Epoxy resin; Thermo-mechanical properties; crosslinking density

作者:王春等,西北工业大学 航天学院,西安

通讯作者:文立华,西北工业大学 航天学院,西安

全文详见中国知网学术期刊优先数字出版。

来源:CSCM_OFFICE 中国复合材料学会

原文链接:http://mp.weixin.qq.com/s?__biz=MjM5MTA2NTk1Nw==&mid=2654407345&idx=3&sn=5489544f811b3362a4acc502cb45d200&scene=0#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn

微软 固化 树脂 环氧 性能 化度 随固化度 交联 玻璃化 收缩率

PRL: 上海交大童华课题组关于玻璃化转变问题取得最近进展

环氧修补砂浆

微软沈向洋:量子计算将会成为未来重要的科技突破口

【行业动态】聚合物为生物环氧树脂复合材料提供增强的固化性能

双马来酰亚胺-聚醚砜复相树脂固化与相行为

【年会综合报道】集“会展赛奖”于一体的环保盛宴——2018中国环境科学学会科学技术年会在合肥圆满闭幕

微软机器翻译新突破:中英新闻翻译水平媲美人类

Science Advances:玻璃是如何形成的?玻璃化过程新机制!

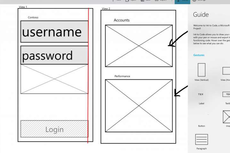

开发设计者福利:新应用能将设计草图直接转化为代码

热收缩率测试仪