科技工作者之家

科技工作者之家APP是专注科技人才,知识分享与人才交流的服务平台。

科技工作者之家 2019-01-24

《复合材料学报》优先在线发表论文。

摘 要:以SiFe合金、沥青为原料,采用机械球磨和高温热解法制备了SiFe@C负极复合材料,并对SiFe及一系列不同热解温度下制备的SiFe@C复合材料进行对比研究。利用XRD、SEM、TEM、X射线能谱仪(EDS)和恒流充放电测试仪对SiFe@C复合材料的物相、颗粒形貌及电化学性能进行表征,结果表明,在850℃热解温度下制得的SiFe@C负极复合材料首次放电比容量达到1376.25mAh/g,首次库仑效率为86.35%,经过70次循环后放电比容量为940.33mAh/g,库仑效率达到98.78%,容量保持率为76.32%,循环性能远高于SiFe和其他热解温度下的SiFe@C复合材料,而且具有良好的倍率性能。

关键词:锂离子电池;SiFe@C负极复合材料;机械球磨;热解温度;碳包覆

Abstract: SiFe@C anode materials were prepared by mechanical ball milling and high-temperature pyrolysis method with SiFe and pitch as the raw materials, and the characteristics of a series of SiFe@C composites prepared at different pyrolysis temperatures were compared with those of uncoated SiFe. The phase composition, morphology and electrochemical performance of SiFe@C anode composites were detected by XRD, SEM, TEM, energy disperse spectroscopy (EDS) and constant current charge-discharge test. The results reveal that the initial discharge specific capacity of SiFe@C composite electrode prepared at 850℃ is 1376.25mAh/g with the initial coulombic efficiency of 86.35%. After 70 cycles, the discharge specific capacity is 940.33mAh/g, the coulombic efficiency is 98.78% and the capacity retention rate is 76.32%, which indicates that its cycling stability and rate capability is much higher than the SiFe and other SiFe@C electrode composites obtained at other temperatures.

Keywords: lithium ion battery; SiFe@C anode composites; mechanical ball milling; pyrolysis temperature; carbon-coating

作者:程成等,昆明理工大学 材料科学与工程学院,云南昆明

通讯作者:肖方明,广东省稀土开发及应用重点实验室,广东广州

全文详见中国知网学术期刊优先数字出版。

来源:CSCM_OFFICE 中国复合材料学会

原文链接:https://mp.weixin.qq.com/s?__biz=MjM5MTA2NTk1Nw==&mid=2654408665&idx=2&sn=eb78abb1a7839f5e94a3ed3c8dea6cfb&scene=0#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn

中国复合材料学会:复合材料相关专业团体标准研制

骨修复复合材料

“蛋结构”材料能有效杀伤肿瘤细胞

陶瓷基复合材料

硼纤维复合材料

原位生长复合材料

科普 | 导热复合材料

科普 | 防热复合材料

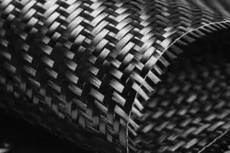

环氧树脂韧性不足,国产碳纤维缺股劲儿

【科普知识】漫步复合材料世界——聚合物复合材料