科技工作者之家

科技工作者之家APP是专注科技人才,知识分享与人才交流的服务平台。

科技工作者之家 2019-03-21

《复合材料学报》优先在线发表论文。

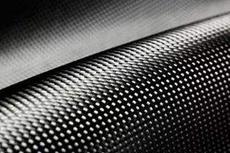

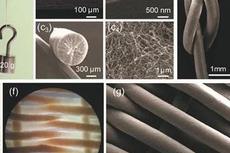

摘 要:为探究不同碳化温度对Co-Mn掺杂碳气凝胶(Co-Mn/CA)的电催化析氢性能的影响,以资源丰富且可再生的木质纤维素为碳源、四水乙酸钴为钴源、四水乙酸锰为锰源,通过水热法制备出Co-Mn/CA。研究发现,纤维素气凝胶碳化后表面形貌发生改变,由片层结构转变为多孔结构,使其活性位点数量增多、电催化析氢活性增加。通过XRD与N2吸脱附对其结构进行了表征处理分析,结果表明,经碳化处理后的碳气凝胶产物以无定型碳为主,经900℃碳化处理后的CA(CA-900)比表面积与总孔隙体积均为最大,分别为958 m2·g-1和0.33 cm3·g-1。电化学性能测试表明,Co-Mn/CA-900表现出最好的电催化剂析氢反应(HER)催化活性,在1 mol/L KOH电解液中,在50 mA·cm-2的电流密度下有着175 mV的过电势,经过10 h的计时电位测试,压降仅为7%,表现出较好的电催化析氢稳定性。

关键词:木质纤维素;碳气凝胶;Co-Mn掺杂;析氢反应;电催化剂

Abstract: In order to investigate the effects of the different carbonization temperatures on the electrocatalytic hydrogen evolution properties of the Co-Mn-doped carbon aerogel (Co-Mn/CA), the Co-Mn/CA was prepared by hydrothermal method using resource-rich and renewable lignocellulose as a carbon source, cobalt acetate tetrahydrate as a cobalt source, and manganese acetate tetrahydrate as a manganese source. The results reveal that after carbonization, the surface morphology of the cellulose aerogel changes from a laminated structure to a porous structure, which increases the active sites and electrocatalytic hydrogen evolution activity. After characterizing the structure by XRD and N2 adsorption and desorption, it show that CA product after carbonization is almost amorphous carbon and the CA after carbonization at 900℃(CA-900) has the largest specific surface area and total pore volume of 958 m2·g-1 and 0.33 cm3·g-1 respectively. The electrochemical performance tests show that the Co-Mn/CA-900 has the best electrocatalyst hydrogen evolution reaction (HER) activity. In 1 mol/L KOH electrolyte, it has an overpotential of 175 mV at a current density of 50 mA·cm-2 and the pressure drop is only 7% after chronopotential test for 10 h, which indicates superior electrocatalytic hydrogen evolution stability.

Keywords: lignocellulose; carbon aerogels; Co-Mn doping; hydrogen evolution reaction; electrocatalysts

作者:臧君娇等,东北林业大学 生物质材料科学与技术教育部重点实验室,哈尔滨

通讯作者:韩广萍,东北林业大学 生物质材料科学与技术教育部重点实验室,哈尔滨

全文详见中国知网学术期刊优先数字出版。

来源:CSCM_OFFICE 中国复合材料学会

原文链接:https://mp.weixin.qq.com/s?__biz=MjM5MTA2NTk1Nw==&mid=2654409095&idx=4&sn=86e8fa8f78ef51b8b4d0348fcad59e35&scene=0#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn

《Nature》:超轻COF/rGO气凝胶

中国科大研制超弹性硬碳气凝胶

科研团队研制超弹性抗疲劳气凝胶

我国学者研制出可耐1300摄氏度高温的隔热防火材料

气凝胶助力太赫兹技术应用

气凝胶纤维领域获进展

石墨烯气凝胶研究取得进展

航空新材料:“升级版”陶瓷气凝胶可耐极端温度

“塑料王”也能变身气凝胶

超轻、绝缘的陶瓷气凝胶可控制最高温度不造成伤害