科技工作者之家

科技工作者之家APP是专注科技人才,知识分享与人才交流的服务平台。

科技工作者之家 2018-12-19

《复合材料学报》优先在线发表论文。

摘 要:采用声发射技术对不同几何尺寸的碳纤维增强环氧树脂基复合材料(CFRP)螺栓连接结构在静力载荷下破坏行为进行了试验研究,比较了不同几何构型下的连接结构的破坏行为与声发射信号之间的映射关系。采用声发射技术对结构损伤过程中的声发射信号进行全程采集与转换,结合CFRP螺栓结构的载荷-位移曲线与宏/细观破坏形貌,分析了幅值、熵曲线和Andrews曲线与破坏行为之间的关系。结果表明:挤压与剪切破坏试件的载荷-位移曲线均呈现出较明显的塑性特征。结构发生挤压与剪切破坏时,声发射信号以为中幅值信号为主,并伴随少量高幅值信号;结构发生拉伸破坏时对应的幅值为中幅值信号。根据熵曲线特征将CFRP连接结构破坏过程分为四个阶段,在损伤演化阶段发生纤维断裂、分层等失效模式,在结构失效阶段以分层失效为主。基于Andrews曲线分析得到挤压和拉伸失效模式在损伤演化阶段会出现多种损伤类型,对于剪切失效模式在结构失效阶段会出现多种损伤类型。

关键词:声发射;复合材料;螺栓连接;破坏;拉伸

Abstract: An acoustic emission technique is used to study the failure behavior of CFRP bolted joints with different geometric sizes under static load, and the relationship between the damage behavior of the joint and the acoustic emission signal under different geometric is compared. The acoustic emission (AE) technology was used to collect and convert the AE in the process of structural damage, and the relationship between the amplitude, entropy curve and Andrews curve and the failure behavior was analyzed by combining the load-displacement curve of CFRP bolted and the macro / meso damage morphology. The results show that the load-displacement curves of bearing and shear failure specimens show obvious plastic characteristics. When the specimen was failure in bearing and shear, the AE is the medium amplitude signal, and a small number of high amplitude signals are accompanied. The medium amplitude signal occurs when the tensile damage was happen. According to the characteristics of entropy curve, the failure process of CFRP joint is divided into four stages, and the failure modes such as fiber fracture and delamination occur at the stage of damage evolution, and the failure is dominated by delamination failure in the stage of structural failure. Based on the Andrews curve analysis, a variety of damage types are found in the failure evolution stage of the bearing and tensile failure modes, and many types of damage will appear in the failure stage of the shear failure mode.

Keywords: Acoustic emission; composite; bolted joint; failure; tensile

作者:唐玉玲等,天津科技大学 机械工程学院 天津市轻工与食品工程机械装备集成设计与在线监控重点试验室 天津

通讯作者:周振功,哈尔滨工业大学 复合材料与结构研究所 哈尔滨

全文详见中国知网学术期刊优先数字出版。

来源:CSCM_OFFICE 中国复合材料学会

原文链接:http://mp.weixin.qq.com/s?__biz=MjM5MTA2NTk1Nw==&mid=2654408347&idx=3&sn=41dac0912af95fc78d063962a28ef951&scene=0#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn

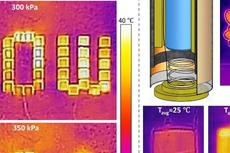

《Nature》子刊:具有反常压阻效应的液态金属柔性导电复合材料

双轴拉伸薄膜

拉伸超过13000倍!超拉伸聚合物重要进展

为什么不良坐姿比端正坐着舒服?看完以后我选择…

金属深拉伸

一种超疏水超疏油的高性能仿壁虎干胶新材料

CICC科普栏目|打破传统!哈佛大学锁志刚院士团队开发出高韧性、低滞后的可拉伸材料

喷丝拉伸

拉伸

纺丝拉伸变形法