科技工作者之家

科技工作者之家APP是专注科技人才,知识分享与人才交流的服务平台。

科技工作者之家 2019-11-24

来源:Nature自然科研

又到了每周一次的 Nature Podcast 时间了!欢迎收听本周由Nick Howe 和 Shamini Bundell 带来的一周科学故事,本期播客片段讨论一种可以同时打印8种材料的3D打印机。欢迎前往iTunes或你喜欢的其他播客平台下载完整版,随时随地收听一周科研新鲜事。

音频文本:

Interviewer: Nick Howe

This is the sound of a printer, but not your standard office job. This printer prints in three dimensions.

Interviewee: Jennifer Lewis

What’s exciting about three-dimensional printing from a materials perspective is you may be able to unlock a much bigger design space.

Interviewer: Nick Howe

This is Jennifer Lewis, a materials scientist from Harvard University. This week in Nature, she and her team are presenting a new type of 3D printer, one which can print a single high-resolution object that is made of multiple different materials. Now, most 3D printed objects are uniform. They are made of just one type of, for want of a better word, ‘ink.’ So, you end up with and object which is entirely made from one type of plastic, for example. Until now, it has been tricky or slow to print objects made of more than one material, and that is all down to nozzles, the bit where the ink comes out. Now there are some types of printers, like inkjet-based 3D printers, that can already print with multiple inks, but they are limited. They can’t print materials that are too viscous or the droplets of ink won’t form properly and will instead form filaments, making precise printing tricky. Extrusion-based printers, however, work differently. They squeeze fluid inks through a nozzle which then harden, and this process can be used to print a greater range of things. But to change the material being printed, you have to stop the print and change the nozzle – not with Jennifer’s printer though.

Interviewee: Jennifer Lewis

So, we’ve developed these three-dimensional printheads which are multi-nozzle and multi-material, and the really big advance is not only that we can print up to eight different materials simultaneously, but that we can switch between these materials at high speeds, so we can switch between them at frequencies of up to 50 hertz.

Sound effect: 3D printer

Interviewer: Nick Howe

To put that into context, this is the sound of the printer switching between materials, at 50 hertz or 50 times a second. Using this technique, Jennifer’s printer can print objects’ materials, or volume elements to give them their technical name, in exquisite detail.

Interviewee: Jennifer Lewis

We can create volume elements now that are on the order of the length and width of a human hair.

Interviewer: Nick Howe

Multiple nozzles and super quick material switching allowed Jennifer’s printer to rapidly make devices from multiple materials. And Jennifer has made all kinds of stuff – a walking robot, for example, with the legs printed from two materials, a soft one for the bendy bits and a hard one for the stiffer components. We actually have a video of the little bot on our YouTube channel and I’d highly recommend checking it out. It is adorable. But anyway, how does the printer work? Well, the secret is some clever use of pressure.

Interviewee: Jennifer Lewis

We’re taking advantage of the material properties of the ink, so these inks have what are called a viscoelastic response. The viscous part means that it will flow under high pressure, so when we apply pressure to the nozzle, the ink flows, but the elastic part means there’s a pressure that we have to exceed in order for the ink to flow.

Interviewer: Nick Howe

This is kind of like the opposite of that classic school room experiment with corn starch and water. You know the one, the gunk that is solid when you hit it, but runs off your hand if you are gentle. It is called Oobleck – another one to google if you haven’t seen it yet. Anyway, unlike Oobleck, Jennifer’s inks do not flow unless you add the right amount of pressure. So, she rigged up multiple channels, each containing different inks and all connected to one nozzle. By carefully controlling the pressure in each channel she could determine which ink flows through the nozzle.

Interviewee: Jennifer Lewis

So, if we’re applying pressure to one ink, that channel is going to flow, and as long as we prevent backflow of that material through the other channels that are filled with different inks, then we’re allowed to be able to print the material of interest and then seamlessly switch, take off the pressure from one ink, apply it to the next, to then change the material on the fly as it’s coming out of the printhead.

Interviewer: Nick Howe

Johannes Overvelde, an engineer who wasn’t associated with this work, is pretty enthusiastic about the potential of this technology.

Interviewee: Johannes Overvelde

I do think that the whole combination of printing multiple materials at these kinds of rates, being able to precisely control the material properties at a sort of pixel level, I think the whole combination of this is new and exciting.

Interviewer: Nick Howe

He’s particularly interested in possibly using the printer to make soft robots.

Interviewee: Johannes Overvelde

And I mean we build robots in our lab. We built a sort of fluidic circuits to control robots in the lab, and all of these things I think we could immediately print using such a device, which for now, it’s quite a tedious process. It’s not that we can’t do it, it’s that it takes a lot of time and experience of people that are doing it, so for me, being able to design something, press a button, and something like that would come out, I think that would for us also be saving a lot of time.

Interviewer: Nick Howe

Now, that’s not to say the printer is without its limitations. At the moment, whilst it can use multiple nozzles at once and swap the materials in the nozzles quickly, the printer can only output one material at a time – all the nozzles have to work in unison. That helps make the prints fast, but it only works with repetitive shapes. It won’t work if there are distinct components in the object being printed. Even so, Jennifer is optimistic about the future use of the printer.

Interviewee: Jennifer Lewis

This technology will enable a huge array of devices, things like flexible electronics, printing rechargeable batteries in three-dimensional architectures, vascularised human tissues that can be used for tissue regeneration and repair. All of these are now possible because many of these devices rely on materials that have limited print windows because they’re either reactive, like epoxies or elastomers, or they contain living cells which can only be printed over about a period of an hour before they start to die, before they lose viability. So, if you have now the ability to construct very complex, three-dimensional objects composed of these reactive or living materials, and do so at very fast timescales, I think the possibilities are really unlimited.

Sound effect: 3D printer

Interviewer: Nick Howe

That was Jennifer Lewis from the University of Harvard in the US. You also heard from Johannes Overvelde from AMOLF in the Netherlands. You can find Jennifer’s paper along with a News and Views article written by Johannes over at nature.com

Nature Podcast每周为您带来科学世界的全球新闻故事,覆盖众多科研领域,重点讲述Nature期刊上激动人心的研究故事。我们将话筒递给研究背后的科学家,呈现来自Nature记者和编辑的深度分析。在2017年,来自中国的收听和下载超过50万次,居全球第二。

↓↓iPhone用户长按二维码进入iTunes订阅

↓↓安卓用户长按二维码进入推荐平台acast订阅

点击“阅读原文”访问Nature官网收听完整版播客

来源:Nature-Research Nature自然科研

原文链接:http://mp.weixin.qq.com/s?__biz=MzAwNTAyMDY0MQ==&mid=2652565450&idx=2&sn=f2db9926be44ebc9e94c416348aaca15&chksm=80cd4144b7bac8525f1bdd528724bb418c8703ac5598e29b59cf4f023e5f2bf42ff518d785d0&scene=27#wechat_redirect

版权声明:除非特别注明,本站所载内容来源于互联网、微信公众号等公开渠道,不代表本站观点,仅供参考、交流、公益传播之目的。转载的稿件版权归原作者或机构所有,如有侵权,请联系删除。

电话:(010)86409582

邮箱:kejie@scimall.org.cn

Nature:凭空(气)发电

浙大再发Nature,王春生Nature Energy等最新文章

蒲慕明院士:建设世界一流期刊关系学术创新的发言权

今年热怕了?Nature子刊:别急,未来4年可能更热

黑磷,再发Nature!

猪年祝你发Nature~

Nature-Tsinghua Conference on Inflammation and Cancer 会议通知

超强磁力 | Nature Podcast

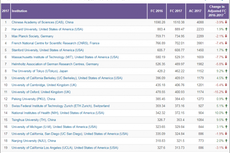

中科院位列2018自然指数榜单全球十大科研机构首位

Science/Nature,Yaghi/武汉大学邓鹤翔Nature Chem.